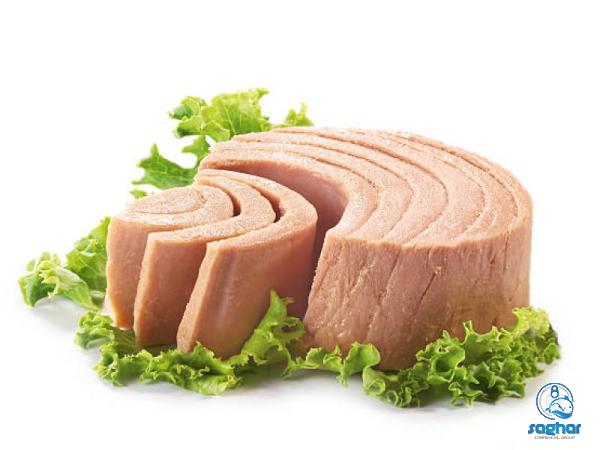

Title: The Price of Light Tuna Canned and Wholesale Production Distribution Introduction: The canned tuna industry has enjoyed steady growth in recent years, with consumers increasingly valuing the convenience, nutritional benefits, and versatility of this affordable source of protein. Light tuna, including skipjack and yellowfin, stands out as an extremely popular choice because of its favorable taste and lower mercury content compared to other varieties. This article provides an overview of the price dynamics of light tuna canned and explores the wholesale production distribution strategies employed by factories in this highly competitive market.

canned food

Price Determinants: Several factors influence the price of light tuna canned, including the cost of raw materials, production and processing expenses, transportation costs, and market demand. Here are the key determinants: 1. Raw Material Costs: The primary cost component in light tuna canned production is the price of tuna fish. Skipjack and yellowfin tuna are commonly used due to their availability, cost-effectiveness, and taste. Market fluctuations in the prices of these tuna species, influenced by factors such as fishing regulations, weather conditions, and geopolitical events affecting fishing grounds, can impact the overall cost of production.

Price Determinants: Several factors influence the price of light tuna canned, including the cost of raw materials, production and processing expenses, transportation costs, and market demand. Here are the key determinants: 1. Raw Material Costs: The primary cost component in light tuna canned production is the price of tuna fish. Skipjack and yellowfin tuna are commonly used due to their availability, cost-effectiveness, and taste. Market fluctuations in the prices of these tuna species, influenced by factors such as fishing regulations, weather conditions, and geopolitical events affecting fishing grounds, can impact the overall cost of production.

Specifications of canned food

2. Processing and Production Expenses: The cost of processing and production includes labor wages, energy expenses, packaging materials, and equipment maintenance. These costs can vary depending on the manufacturing process adopted, the automation level of the factory, and the geographical location of the production facility. Streamlining and optimizing production can help minimize costs and improve profitability. 3. Transportation Costs: Transportation costs impact the final market price of light tuna canned products. These costs involve various elements, including fuel prices, distance traveled, transportation mode (e.g., sea, air, road), and import/export tariffs. Efficient logistical operations and optimized distribution networks are crucial for maintaining competitive pricing in wholesale and retail markets.

2. Processing and Production Expenses: The cost of processing and production includes labor wages, energy expenses, packaging materials, and equipment maintenance. These costs can vary depending on the manufacturing process adopted, the automation level of the factory, and the geographical location of the production facility. Streamlining and optimizing production can help minimize costs and improve profitability. 3. Transportation Costs: Transportation costs impact the final market price of light tuna canned products. These costs involve various elements, including fuel prices, distance traveled, transportation mode (e.g., sea, air, road), and import/export tariffs. Efficient logistical operations and optimized distribution networks are crucial for maintaining competitive pricing in wholesale and retail markets.

buy canned food

4. Market Demand: Market demand is a significant driver of the price of light tuna canned, as it determines the overall sales volume and market competitiveness. Factors that influence demand include consumer preferences, nutritional awareness, promotional activities, product differentiation, and competition with other protein sources. Understanding and adapting to changing consumer preferences can influence pricing strategies to capture market share. Wholesale Production Distribution: To ensure a steady supply and demand balance, as well as efficiently cater to consumer needs, tuna canning factories employ various wholesale production distribution strategies. These strategies help manage inventory, optimize transportation logistics, and facilitate prompt delivery. Here are a few key aspects of wholesale production distribution in the light tuna canned industry:

4. Market Demand: Market demand is a significant driver of the price of light tuna canned, as it determines the overall sales volume and market competitiveness. Factors that influence demand include consumer preferences, nutritional awareness, promotional activities, product differentiation, and competition with other protein sources. Understanding and adapting to changing consumer preferences can influence pricing strategies to capture market share. Wholesale Production Distribution: To ensure a steady supply and demand balance, as well as efficiently cater to consumer needs, tuna canning factories employ various wholesale production distribution strategies. These strategies help manage inventory, optimize transportation logistics, and facilitate prompt delivery. Here are a few key aspects of wholesale production distribution in the light tuna canned industry:

canned food + buy and sell

1. Direct to Retailer: Some tuna canning factories opt for a direct-to-retailer distribution model. In this scenario, the manufacturer sells directly to major retailers, such as supermarkets and foodservice providers. By bypassing intermediaries, factories can maintain direct control over pricing, product display, and promotional activities. This approach can enhance profit margins, reduce delivery time, and foster stronger relationships with retailers. 2. Distribution Centers: To ensure efficient distribution operations, some factories establish regional or central distribution centers. These centers act as logistical hubs, receiving bulk shipments from production facilities and redistributing them to various retailers or wholesalers. This approach enables factories to employ economies of scale, consolidate shipments, and streamline transportation logistics, resulting in cost savings and improved efficiency. 3. Distributor Networks: Many light tuna canned factories partner with local or international distributors to expand their market reach. Distributor networks enable factories to access new markets, reach smaller retailers, grocery chains, and even overseas buyers. These arrangements often involve long-term contracts and agreements regarding pricing, product exclusivity, marketing support, and order volume commitments. 4. E-commerce and Online Platforms: In recent years, the rise of e-commerce and online platforms has revolutionized wholesale production distribution. Tuna canning factories now leverage online platforms to directly reach end consumers, independent retailers, and foodservice providers. This approach reduces distribution costs, facilitates real-time inventory management, allows for customized orders, and enables factories to adapt to changing market trends swiftly. Conclusion: The price dynamics of light tuna canned are influenced by various factors such as raw material costs, production expenses, transportation logistics, and market demand. Tuna canning factories employ wholesale production distribution strategies to manage inventory and transportation, and ensure efficient delivery to retailers and end consumers. Understanding these dynamics is crucial for factories to remain competitive in this dynamic market and cater to the growing demand for light tuna canned products.

1. Direct to Retailer: Some tuna canning factories opt for a direct-to-retailer distribution model. In this scenario, the manufacturer sells directly to major retailers, such as supermarkets and foodservice providers. By bypassing intermediaries, factories can maintain direct control over pricing, product display, and promotional activities. This approach can enhance profit margins, reduce delivery time, and foster stronger relationships with retailers. 2. Distribution Centers: To ensure efficient distribution operations, some factories establish regional or central distribution centers. These centers act as logistical hubs, receiving bulk shipments from production facilities and redistributing them to various retailers or wholesalers. This approach enables factories to employ economies of scale, consolidate shipments, and streamline transportation logistics, resulting in cost savings and improved efficiency. 3. Distributor Networks: Many light tuna canned factories partner with local or international distributors to expand their market reach. Distributor networks enable factories to access new markets, reach smaller retailers, grocery chains, and even overseas buyers. These arrangements often involve long-term contracts and agreements regarding pricing, product exclusivity, marketing support, and order volume commitments. 4. E-commerce and Online Platforms: In recent years, the rise of e-commerce and online platforms has revolutionized wholesale production distribution. Tuna canning factories now leverage online platforms to directly reach end consumers, independent retailers, and foodservice providers. This approach reduces distribution costs, facilitates real-time inventory management, allows for customized orders, and enables factories to adapt to changing market trends swiftly. Conclusion: The price dynamics of light tuna canned are influenced by various factors such as raw material costs, production expenses, transportation logistics, and market demand. Tuna canning factories employ wholesale production distribution strategies to manage inventory and transportation, and ensure efficient delivery to retailers and end consumers. Understanding these dynamics is crucial for factories to remain competitive in this dynamic market and cater to the growing demand for light tuna canned products.

Your comment submitted.